So for quite some time I’ve been trying to print ABS on an SX1. Looking on the internet, it seems people where doing it without to much of an issue, but every hint or tip I implemented was only making it worse. All the changes resulted in droopy and splitting prints.

Turns out my macgyvered enclosure was doing too good of a job. And despite the main rule was not having any draft. I tried as a last effort to turn on the cooling fan anyway. Which resulted in “THE BEST CONSITANCY AND OVERHANGS EVER!”

So my tip too you: just use cooling anyway.

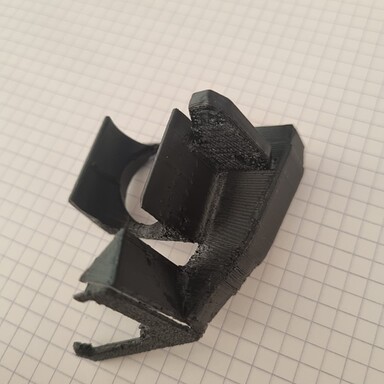

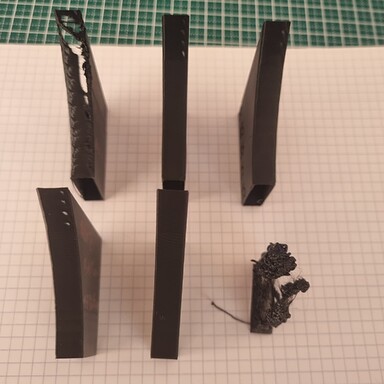

Average result

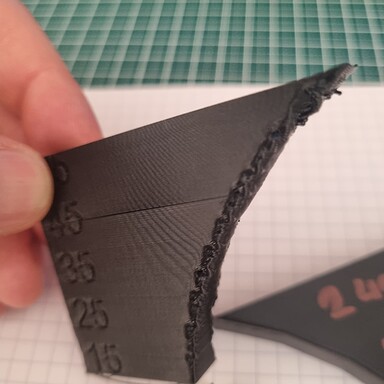

Test print #1 240°C no cooling 30mm/s

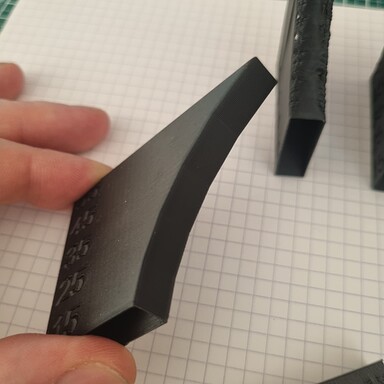

Test print #156 240°C 50% cooling 30mm/s

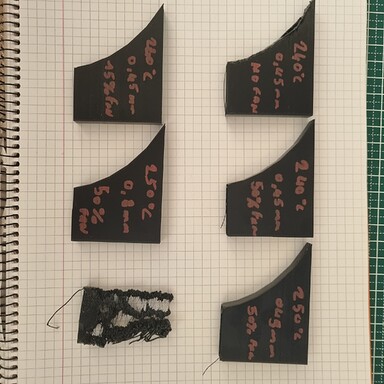

Some other results