Let me first start with some beauty shots. The Resurrection model from Kaoss is really cool.

Now that you’ve seen how you can print with the AMS, let’s talk a bit about the printing issues I have encountered during this print.

The models were sliced with Bambu Slicer. I wanted to do four models but the slicer was using about 12GB of RAM and slicing took more than an hour. Sure, it wasn’t on the fastest computer out there, but I still expected a bit better. I only managed to slice three models, without crashing.

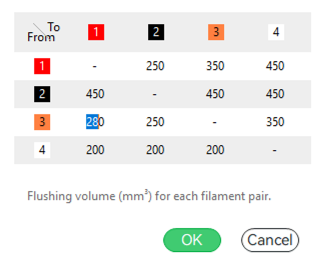

I tuned the purge amount in the slicer, according to the settings below:

I used a lot more purge for darker colors like black and red when transitioning to lighter colors, but for white, I need an extra ~100mm3 for a cleaner output. I also didn’t use a purge tower hoping that I would use less filament but this caused some small zits of filament on the model which was printed first.

These small zits can be solved with a purge tower, so I think there’s no way to completely get rid of it. You might even get a faster print by shortening the purge amount in the back chute and increasing the size of the purge tower.

In the image below, you can also notice where the printer slowed down for overhangs. The extrusion consistency changes and this can also be seen on the model. This issue could be fixed by tuning the print speeds so that the external walls have the same printing speed as the overhangs.

A small issue on the left eye can be seen on the model. This is caused because of a filament tangle in the AMS which was probably caused by me.

The printer stopped and waited about 8 hours for me to interact with it. I pulled out the filament, got rid of the tangle and resumed the print.

Unfortunately, the printer did not perform another purge, and started printing with not enough filament in the hotend. When it started printing the eye, there was no filament in the nozzle so it missed a layer.

The Z seam also needs careful positioning. I forgot to align it according to my needs, and as you can see, the Smart alignment isn’t super smart with these models. All three prints have different layer starts.

Finally, let’s talk about waste. The print tool about 74 hours to complete. I don’t have an exact number because I can’t be sure when the print stopped with that filament tangle.

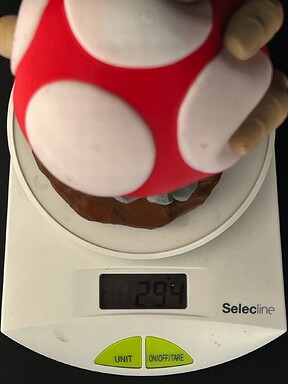

Every model weighs ~294g so ~885g of filament was used to print the models.

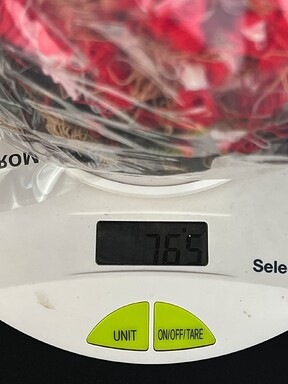

The purge amount weighs ~765g.

Quite a lot of waste. Remember that this amount of waste would be the same if I were to print a single model, or the three models I did now. You decide if it’s a lot or not.

I managed to print with 6 colors by replacing the brown filament with red, and grey with black after the bottom sections were printed. The change is super simple to do. Just remove the filament and insert the new one into the AMS.

If you have other questions, please post below. It’s hard for me to reply on every question on multiple social media posts, and I would like to keep the information contained into a single thread. ![]()