- 3D Printer Model: AnyCubic Kobra 2

- Slicer: Prusa

- Hardware Setup: Stock

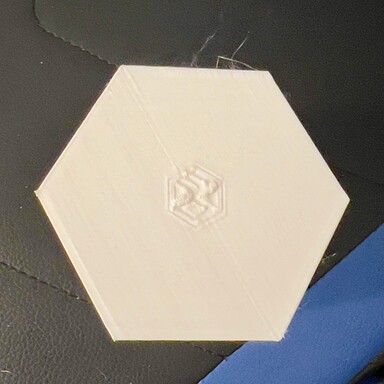

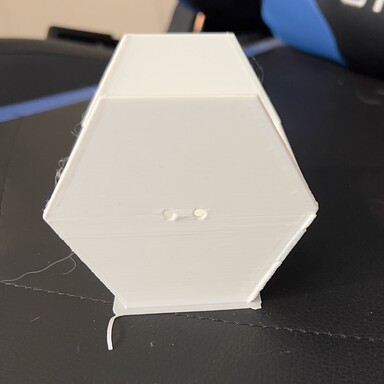

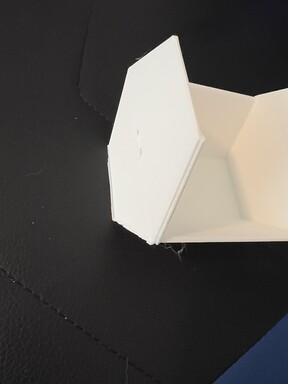

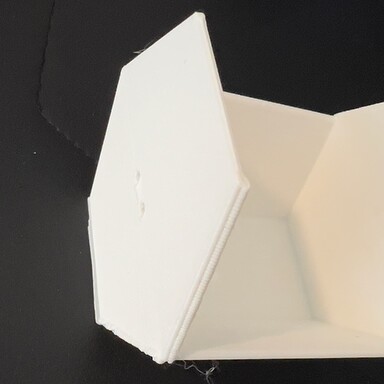

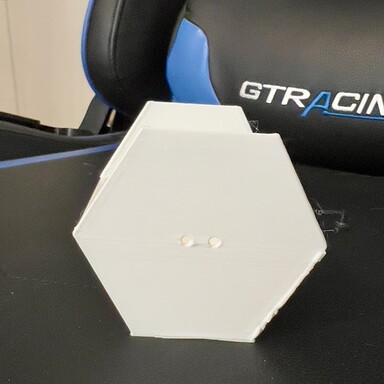

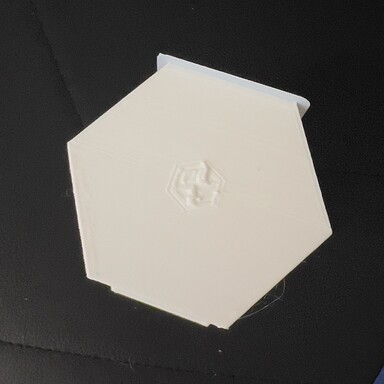

- Problem description: I’m having an issue with either the motion system, extrusion, or both. I’m not 100% sure which. When the print needs to turn a 90° corner, it sometimes will produce an overly thick corner. But sometimes not. On the test batches I ran, 2/4 corners were good on even the goopiest models. The straight-run lines (horizontal walls) were fine. My gut says it’s motion / motor related, since it seems to only crop up on sharp X-to-Y turns. It also appears on the small emblem on the back of each drawer which is a more intricate shape.

- What I tried: Dropped speed to 80% (stable mode).

These two were printed at the 80% speed which reduced the thickness on those two corners. It’s thicker, but not bumpy / toothpaste-squeezy.

It was always those two corners (front left and rear right, from the perspective of the model). The models were arranged aligned with the print bed.

I am not familiar with the Kobra 2, but I would check the retraction value in the slicer.

The corner is also where the Z seam is probably printed, contributing to this problem. You could try re-positioning the seam in a less visible location.

Besides that, I would check if the firmware on the Kobra 2 has Pressure Advance/Linear Advance calibrated which can produce worse results if not done right.

> the firmware on the Kobra 2 has Pressure Advance/Linear Advance calibrated which can produce worse results if not done right.

Not visible in the GUI, no. The options are leveling, filament loading, and speed multipliers.

I will investigate these, thanks.