Good evening everyone!

So, I installed Klipper on my Anycubic Vyper a while ago after reading some post about how it being the cure for baldness and rather than keep having to re-compile my own Marlin version just because I want to tweak a setting.

I seem to have some problems with getting a good PA result, attaching images below. Bulging corners causes for example other prints with need for precision to not work at all.

Using Cura.

Settings:

Filament: eSUN PLA+ Grey

Temp: E 205 B 60

Speeds: Outer perimeters 50mm/s, infill and inner perimeters at 100mm/s, Initial layer 25mm/s

Retraction: 2.5mm at 30mm/s

Cooling: 70% with dual 5015 blower fans

Klipper is configured with a PA value of 0.489 from the formula of (0 + 24.45 * 0.020) as given by the documentation.

Got the measurement from a print of the PA model from Klipper github.

Am I doing something wrong here? Anyone else with a vyper running klipper that care to share some knowledge on getting this right?

Try testing with a larger model, ex: 200% calibration cube. It will give you more accurate results.

But don’t forget to calibrate flow rate first, before doing the PA calibration.

Hi and thanks for the suggestion.

I did the following things.

- Disabled PA by removing the set values in my printer config

- Measured sections of the filament, used your calculator and was surprised to see an actual value of ~1.71 (I thought eSUN was good…

)

)

- Ran flow calibration with a hollow cube, came up with that 102% of flow in Cura should be set

- Performed the process of PA calibration, now measured 21.64mm giving 0 + 21.64 * 0.020 = 0.4328 to set as PA

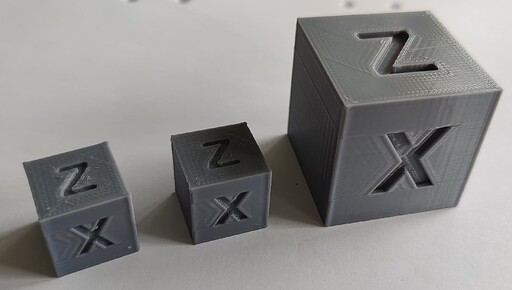

Then I printed three calibration cubes, with variation on PA and scale.

Leftmost: No PA set

Center: PA set to 0.4328

Right: PA set to 0.4328 but cube is 200% scaled

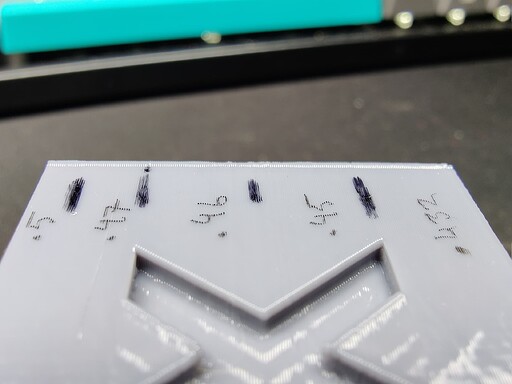

Closeup of the last one.

Still seem to be bad rounded corners and edges? Both on the X and to the right…

Do I have to do anything else than set the pressure_advance value in the extruder section of the printer config?

I would also recommend you to check the PTFE couplers during printing. If you notice a small movement, then you need to cut a small piece of tube an insert it again to eliminate that.

You can also increase the PA value a tiny bit more. For ex. 0.45-0.46 and see what you get.

Also note that Sunlu Grey seems to have a higher PA value compared to other brands, so you will probably need to tune that again if you plan to change filaments

I marked the bowden tubes and observed and I could not see that they moved in/out from the couplers. Especially the extruder since the one from Bondtech grips quite well it seems.

Tried printing a new 40x40 cube and changing PA value myself in intervals.

Can’t really see much change?

Even tried to print a regular 20x20mm with .7 PA, still bulging corners.

What’s odd is that the PA calibration cube thingy show actual PA change while these not so much?

I use the PA test on this page GitHub - AndrewEllis93/Print-Tuning-Guide

I get better results with the PA here, than with the tower method. Follow the steps on the page.

Thanks for the tip! Checking it out right now.

It’s a great guide in general. It’s my tuning go-to.