Tried to run the part and could not get the ABS to stick to the bed.

I figured out how to raise the temps of the nozzle and the bed. The bed has a max temp of 110.

I gave up and ordered some PLA which is what the OWL demo print used and it worked fine for the OWL…

So I will wait until it gets here and give it another try.

I was about to tell you that ABS printing is a little bit tricky…

To start with, you would need a minimum of 100º on bed and about 250 on hotend and, what is more important, a printing enclosure. Otherwise you would be experiencing some lifting as you have reported.

I do not think PLA to be a good material for functional parts but it is easy to print.

The part will be very low use, but what would you recommend?

If it is going to be exposed to direct sun light, ABS. ABS withstands 100º - 105º and it has got very good impact resistance.

Another possibility would be PET-G. PET-G withstands about 80º, very good layer adhesion and torsion tolerant.

Unfortunatelly, PLA is the worst choice. Weak and very low thermal resistance, about 60º. On the other hand, printing PLA is very easy and parts usually turn out very nice.

I would recomend ABS.

If I could use ABS I would have it made.

I’ll try the PLA and if it does not work then the Pet-G.

Are your temps in “F” or “C” ?

Thanks

G

Ya, I know.

Temperatures are in C.

Progress?

Been trying to do this and have been fiddling with the temps as the PLA was not sticking.

Finally upped it to 240 and 80 and it sticks.

Took at the run at the program it it started off fine so I went in the house for a minute and when I came back the part had been knocked off the bed.

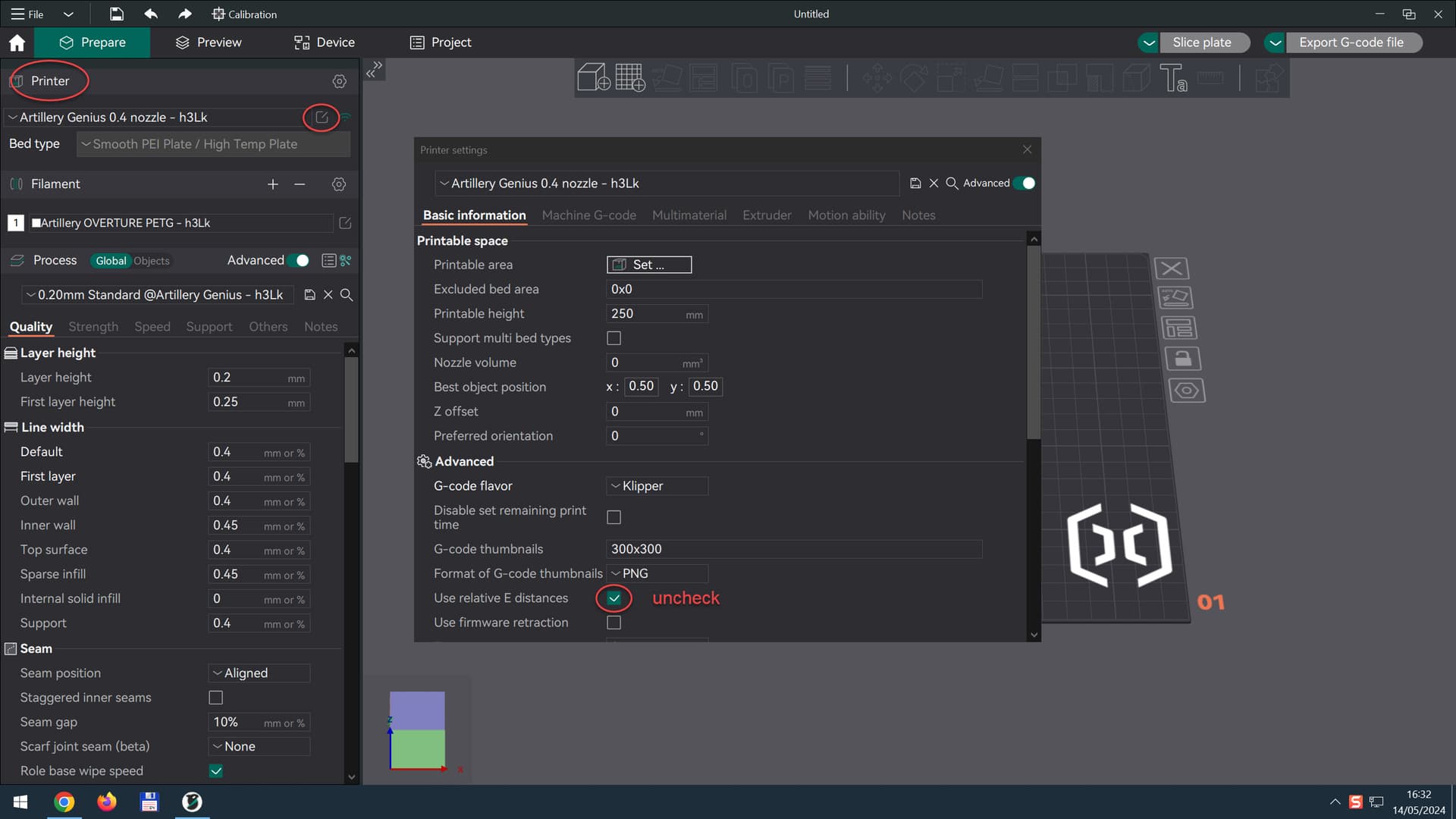

Got to looking at the code and found the following lines. You can see that it is zooming along and then it gets to this part and it lowers the nozzle and zooms around. This appears to happen twice that I have found…

G1 X60.471 Y61.628 E21.62077

G1 X61.619 Y60.48 E21.70177

M205 X8.18 Y8.18

G1 F1500 E15.20177

;MESH:GregsPART.stl

G0 F1800 X62.831 Y62.885

G0 X67.67 Y72.486

G0 X66.754 Y71.729

G0 X111.708 Y167.824

G0 X111.706 Y167.725