Wanted to write a brief review of my experience with the new Sapphire Plus SP-5. Didn’t take too many photos or use the printer too much as I purchased it for a kit to build upon, but thats about all I can say about it. This is not a printer for a novice user. It will require trouble shooting and patience right from the start, especially in stock configuration. Here is a list of notes I took during the build.

PSU properly grounded

Fiddly phillips screws impossible to remove for z switch install + access panels (need small electronics bits+pliers+patience)

Be sure to put gantry on the right way (no logo anywhere so an easy mistake with such poor instructions)

Sent 2 wrong corner extrusions (all 4 corners are unique, I was sent 2 sets of the same extrusion. Was able to compensate using corner brackets)

New heated bed cable management and mount

No info on installing glass print bed (shit manual)

Some linear rails poorly cut (not remotely straight, but shouldn’t affect function)

Default language was English

Rails dirty, need cleaning + no included lubrication for them or threaded rods

Now includes a motor off feature that I believe was previously not available

y limit switch does not work and will require further investigation (switch was in the wrong place on the motherboard)

Belts not tensioned properly

Insane under extrusion (Not gonna bother trouble shooting as I planned on upgrading the hotend and extruder from the get go)

May add pictures at some point, but for now just wanted to share my experience.

1 Like

wish I could post more info but my printer is still in the box due to other projects on the table, hopefully soon but I already know I will swap certain things especially around hotend straight away, did you get bltouch or at least holder in your package?

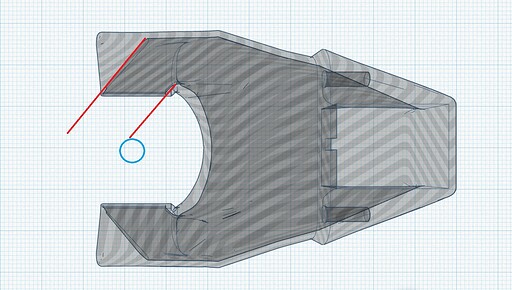

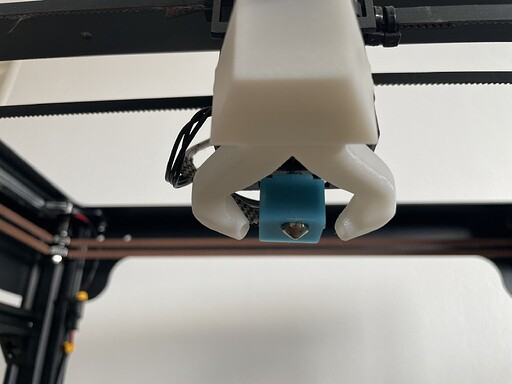

final version (for now) , couldn’t get below 290 grams fully loaded which is still bit high to my liking, I guess if it’s printed out of ABS I could save 10-15 grams but then I would sacrifice the heat resistance of this resin print and would have to redesign it = nono

2 Likes

Looks great!

Is the holder printed in resin?

yup, funtodo heat resistant industrial blend resin

No BL touch came with my printer. Filament runout sensor was included. I just finished building a Voron Mobious M4 that I will be throwing on. Waiting on a 24v 5015 and 4040 fan to come in to swap to an e3d v6 setup. Klipper will be in the future but just want to get a reliable printer for now. I will add more content here as I get more time on the printer.

seen your post on discord, stock firmware is total crap without proper options to adjust it so grab one of these and test it, that’s what I plan to do for the start, yours should be V4 firmware just pick the one with manual bed leveling , 5x5 grid and colour UI

Release Version 1.1.2 Release · Ideagen3d/SapphirePlus-Unified-Firmware · GitHub

1 Like

I presume you have it hooked up via USB cable?

This is one of the next places I was going to look to solver the issue, thanks for making my life easier. I hooked it up and put esteps value in via pronterface. I also resorted to putting the esteps in the start gcode but still cant solve it. Since they were only $9 I purchased 2 new stepper drivers that will arrive tomorrow just to cover all bases.

Sadly new firmware didnt fix and its extruding the exact same amount as before. I ended up needing the v3 software as I have the robin nano 1.2 board.

Swapping steppers didnt seem to fix it either :\ im stumped

SOLVED THE ISSUE! So partly sad on my part, partly sad on Two Trees side. Sapphire Plus has a microstep value of 32. This is why when I calibrated thinking things were busted my value was so high, but I didnt realize the calibrated esteps value I was getting was exactly twice. From the factory the stock extruder has esteps value for a microstepping value of 16 for a 2:1 geared extrudder (bondtech clone). So from the factory it was pumping out exactly half the amount of filament it should have causing the under extrusion. Now with my 4:1 gear ration Mobious M4 extruder the standard esteps value of 560 gets multipled by 2 and I get an esteps value of 1120 which is what I was getting when trying to calibrate the extruder during troubleshooting.

was gonna ask you if you’ve checked the Vref and microstep values when you changed your extruder motor, great you’ve been able to solve it

This drives me nuts last 2 days, I changed everything in the filament path but nothing helped, I was able to print test cube at lower speed at the end but no benchy so far, for now it just stops extruding at any stage of the print as shown on the picture and very hot extruder motor starts skipping and stripping filament, btw. I can still push the filament through the nozzle by hand or by manual extruding so there’s no clog or jam in the hotend, it’s really happening only during print and I tested several filaments and temp setting with not much difference, picture shows just few of them, rest is already in da bin…

Plan for tomorrow: lower the retraction speed and loosen the extruder idler tension to prevent potential damage of the filament before it gets to the nozzle as found and suggested here by Chris,

another day in paradise, changed extruder motor, wen’t back to stock mount and back to original setting just to find out another failed benchy, started to print another cube as the last one wen’t pretty ok and realised the problem really occurred only during set of quick and continues retractions so the culprit has to hae something to do with retraction, went back to cura but couldn’t find anything faulty, decreased the retraction distance even further just to realise 1 field turned red and then the bulb lit on, stupiiiiiiiid me, for some reason I expected with new machine my old way of setting it up will be sufficient, of course there’s another field called Minimum Extrusion Distance Window which should always be aligned with retraction distance, bloody hell, how dumb I am  , always go through every field in cura when changing profile, doing update or adding new machine so no field is missed even if it doesn’t sound/looks important !!!

, always go through every field in cura when changing profile, doing update or adding new machine so no field is missed even if it doesn’t sound/looks important !!!

Here we go, 80mm/s 0.2 layer height, nowhere near perfect especially with crappy stock fans and no tweaking but I’m crazy happy to be able to print without troubles

You are printing silk filament at 80mm/s

This won’t give you a good consistent finish and the prints will also have poor layer bonding.

I recommend keeping the speeds to less than 50mm/s for good results.

If you want to tune print speeds, use a regular filament.

Yeah, sure, I did test it at such speed just to find out if the problem occurs again at higher speed and retractions, this wasn’t test print to prove capability of the printer and its quality level

and due to fact that 80% of my filament collection is silk, ultra silk or glitter I had to test it with one of them

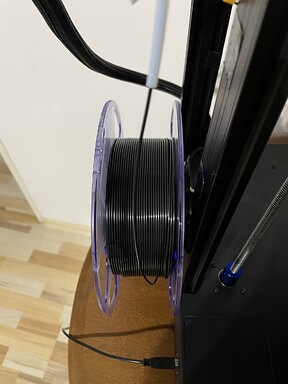

treated myself new spool holder, couldn’t find any suitable so remixed this one with more slim design and added side mount so it can be flush mounted with the 2020 extrusion

and then they’ve asked if I have tools holder, sure I said…

remixed Flsun holder I’ve been using in da past on my QQS-PRO

what ever I print on this printer looks great  , weird…

, weird…

…next day in printing paradise…

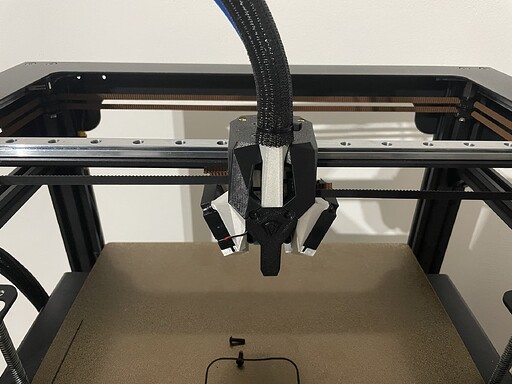

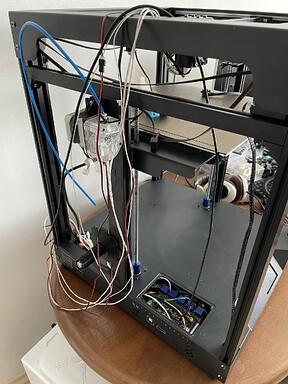

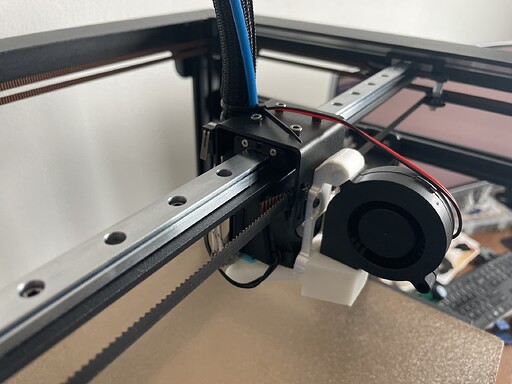

Decided to redo the wiring, exchanged couple of mounts in the meantime, finally fixed those noisy fans and wasted several hours of troubleshooting fan ducts from german project (suggested by 3DPB) so decided to create my own, pictures and final solution below, today’s benchy came out really nice (except front overhangs) considering another 100mm/s test so printing something more appealing atm, any questions just ask

1 Like